Welcome back everyone! In this blog entry I will be solving a case study using Design Of Experiments as well as sharing my reflections for DOE and the practical I did.

What is Design Of Experiment?

- It is a statistics-based approach to designing experiments

- A methodology used to obtain knowledge of a multi-variable process in fewest trials possible

- It is the backbone of product design

Types of data analysis

- Full factorial data analysis

- Using data gathered from all possible runs

- More accurate due to larger sample size

- Fractional factorial data analysis

- Uses data gathered from selected possible runs

- More efficient and resource-effective

Case study

In this case study, I will be investigating the cause of the loss in popcorn yield.

Three factors have been identified as the possible cause. They are:

- Diameter of bowls to contain the corn

- Microwaving time

- Power setting of microwave

In order to determine the impact of each factor, experiments will be conducted with each of the factor having a 'low' and a 'high' value. The following are the two sets of values for each factor:

|

|

‘Low’ Value (

- ) |

‘High’ value

( + ) |

|

Factor A - Diameter of

bowls |

10 cm |

15 cm |

|

Factor B - Microwaving time |

4 minutes |

6 minutes |

|

Factor C - Microwave

power |

75% |

100% |

Using the above values, an experiment was conducted and here are the result:

|

Run order |

Factor A (Bowl

diameter) |

Factor B (Microwave

time) |

Factor C (Microwave

power) |

Un-popped

kernels (grams) |

|

1 |

+ |

- |

- |

3.78 |

|

2 |

- |

+ |

- |

2.78 |

|

3 |

- |

- |

+ |

0.74 |

|

4 |

+ |

+ |

- |

1.78 |

|

5 |

+ |

- |

+ |

0.95 |

|

6 |

+ |

+ |

+ |

0.32 |

|

7 |

- |

+ |

+ |

0.78 |

|

8 |

- |

- |

- |

3.12 |

To begin analysis on each of the factors, I will be using both full factorial and fractional factorial methods to plot a graph to visually represent the impact of each factor.

I will be using Microsoft Excel to assist me in plotting the graphs.

FULL FACTORIAL ANALYSIS

For full factorial data analysis. all the data from the 8 runs will need to be taken into account. Hence, in Microsoft excel I created a table and inputted the data for all the runs.

I then found the average values of each factor at their 'high' and 'low' modes.

Afterwards, I created a graph utilising the average values from the data.

A steep gradient from the graph tells us that there is a significant change in the amount of un-popped kernel between the 'HIGH' and 'LOW' value of a factor. While a gentle gradient tells us that there is not much change in the amount of un-popped kernel between 'HIGH' and 'LOW' value of a factor.

Therefore from the graph, it can be inferred that factor C has the greatest impact on the amount of un-popped kernel due to it having the steepest gradient. It is followed by factor B which have the second steepest gradient and impact on the amount of un-popped kernel. Finally, factor A had the least steep gradient as well as the least amount of impact on amount of un-popped kernel.

Effects of each factor

As factor A (bowl diameter) increases, the amount of un-popped kernel decreases.

As factor B (microwave time) increases, the amount of un-popped kernel decreases.

As factor C (microwave power) increases, the amount of un-popped kernel deceases.

Interactions effects

(A x B)

At LOW B,

Average of low A = (0.74 + 3.12)/2 = 1.93

Average of high A = (3.78 + 0.95)/2 = 2.365

Total effect of A = (2.365 - 1.93) = 0.435 (increase)

At HIGH B,

Average of low A = (2.78 + 0.78)/2 = 1.78

Average of high A = (1.78 + 0.32)/2 = 1.05

Total effect of A = (1.05 - 1.78) = -0.73 (decrease)

The gradient of both lines are different ( LOW B is +ve and HIGH B is -ve). Therefore there is significant interaction between factor A and factor B.

(A x C)

At LOW C,

Average of low A = (2.78 + 3.12)/2 = 2.95

Average of high A = (3.78 + 1.78) = 2.78

Total effect of A = (2.78 - 2.95) = -0.17 (decrease)

At HIGH C,

Average of low A = (0.74 + 0.78)/2 = 0.76

Average of high A = (0.95 + 0.32)/2 = 0.635

Total effect of A = (0.635 - 0.76) = -0.125 (decrease)

The gradient of both lines are marginally different. Therefore there is interaction between factor A and C but the interaction is small.

(B x C)

At LOW C,

Average of low B = (3.78 + 3.12)/2 = 3.45

Average of high B = (2.78 + 1.78)/2 = 2.28

Total effect of B = (2.28 - 3.45) = -1.17 (decrease)

At HIGH C,

Average of low B = (0.74 + 0.95)/2 = 0.845

Average of high B = (0.32 + 0.78)/2 = 0.55

Total effect of B = (0.55 - 0.845) = -0.295 (decrease)

The gradient of both lines have a noticeable difference. Therefore there is some interaction between facto B and factor C but not by much.

Overall, using full factorial data analysis, I was able to find out that factor C (microwave power) is the most impactful on amount of un-popped kernels. Followed by factor B (microwave time) which have a decent impact on amount of un-popped. And finally factor A (diameter of bowl) which have the least impact on amount of un-popped kernels among the three factors.

Even though each factor have different levels of impact on the amount of un-popped kernels, all of them will reduce the amount of un-popped kernel when their values are increased.

Hence, the values of all three factors should be set as high as possible to lower the amount of un-popped kernel and minimise loss of popcorn yield.

Additionally, I was able to find out that all three factors have interactions with each other. With minimal interactions between factors (A x C) and (B x C) but significant interaction between factors (A x B).

After conducting data analysis with full factorial method, I will now be using fractional factorial method to investigate the same case study.

FRACTIONAL FACTORIAL ANALYSIS

Since full factorial analysis does not use data from all of the runs, I will need to carefully select the runs to be used for data.

Hence, among the 8 runs collected I will only be selecting the following 4 runs:

|

Run order |

Factor A (Bowl diameter) |

Factor B (Microwave

time) |

Factor C (Microwave

power) |

Un-popped

kernels (grams) |

|

1 |

+ |

- |

- |

3.78 |

|

2 |

- |

+ |

- |

2.78 |

|

3 |

- |

- |

+ |

0.74 |

|

6 |

+ |

+ |

+ |

0.32 |

Using the data from these 4 runs, I created a graph for fractional factorial analysis.

A steep gradient from the graph tells us that there is a significant change in the amount of un-popped kernel between the 'HIGH' and 'LOW' value of a factor. While a gentle gradient tells us that there is not much change in the amount of un-popped kernel between 'HIGH' and 'LOW' value of a factor.

Therefore from the graph, it can be inferred that factor C has the greatest impact on the amount of un-popped kernel due to it having the steepest gradient. It is followed by factor B which have the second steepest gradient and impact on the amount of un-popped kernel. Finally, factor A had the least steep gradient as well as the least amount of impact on amount of un-popped kernel.

Effects of each factor

As factor A (bowl diameter) increases, the amount of un-popped kernel increases.

As factor B (microwave time) increases, the amount of un-popped kernel decreases.

As factor C (microwave power) increases, the amount of un-popped kernel deceases.

Conclusion Fractional Factorial

Similarly to full factorial method, factor C is the most impactful followed by factor B and factor A.

Although all the values factors have different amount of impact on amount of un-popped kernels and loss in yield of popcorn. It has shown that altering the values of each factor can minimise the lost yield of popcorn.

However, there is a difference in effect of factor A. In full factorial the value of factor A have an inverse relationship with amount of un-popped kernels while in fractional factorial the value of factor A actually has a direct relationship. As seen from the fractional factorial graph, the increase in value of factor A actually leads to an increase in amount of un-popped kernels.

This discrepancy is due to fractional factorial method using only parts of all the possible data which results in it being more efficient and resource-effective but with the trade-off of missing some information.

Hence, when conducting similar experiments in the future, I must weight the advantages and subsequent trade-off when choosing between fractional factorial and full factorial data analysis methods.

LINK TO EXCEL SHEET

LEARNING REFLECTIONS

Tutorial

I was first introduced to Design Of Experiment in my tutorial lesson on the same topic. In the beginning of the lesson, I thought this would be a simple topic since I believed it would just be adjusting the parameters of an experiment to optimise it. However, I soon learnt that there was much more to DOE.

For instance, I had always thought brute forcing through all the possible situations were the only way to optimise the parameters for an experiment or process. I instantly changed my mind once I learnt about the possibility of doing fractional factorial method. Not only is it much more efficient compared to running through all possible data, it is also much less stressful and easier to use. This has opened an entire new method to optimisation for me. However, this was actually not the first time I have been introduced to fractional factorial method and DOE.

In a previous module CP5202, I was tasked to use DOE to identify optimal parameters to extract the maximum amount of coffee solubles from coffee beans.

In the practical, as a class we adjusted parameters such as temperature, stirrer speed and size of coffee beans to determine best parameters for extracting coffee solubles. We did not know it at the time but that was an example of DOE.

This just shows that every module I have taken is important and that they are all connected to each other. I will need to continue learning from my lecturers and fellow students as my understanding is still lacking and I have likely missed many important lessons that can not only improve my time as a student but also my daily life.

I will also continue honing my skills in DOE as it is likely to prove useful later on especially during prototyping of my group product in this exact module.

Practical

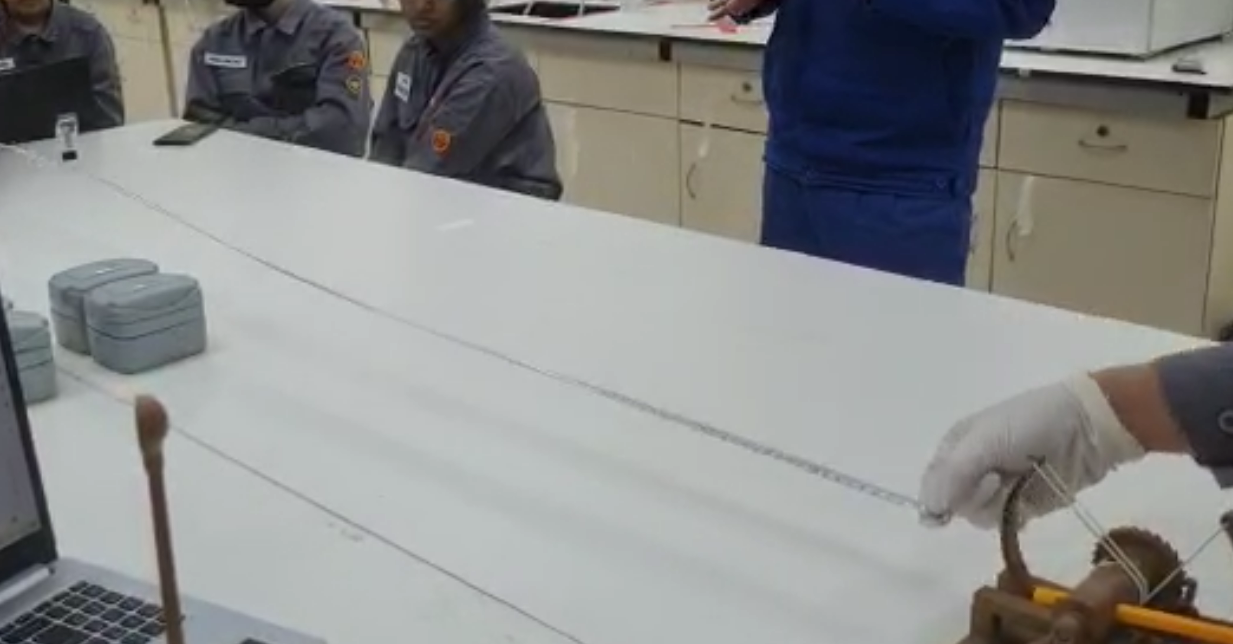

After learning about DOE in the tutorial lesson , I also got the opportunity to take part in a practical utilising everything I have learnt. The practical was extremely exciting as it includes a catapult!!

In this practical the entire class was grouped into groups of 5 to complete the experiment.

The objective of the experiment was to use DOE to identify the effects of 3 factors at 2 levels each have on the distance travelled by a ball launched by the catapult as well as determining the most significant effect of the 3 factors.

The factors include:

- Arm length of catapult

- Projectile weight

- Stop angle of catapult

Additionally, within our group of 5 we split into two smaller groups. One group performed full factorial data analysis while the other performed fractional factorial data analysis.

Although I found it quite daunting at first since there were over 90 runs in total, with the help and support from my fellow groupmates we were able to complete it quite quickly.

I am extremely grateful for all the assistance I received as I definitely would had trouble completing all the the full factorial runs.

After the entire class has finished gathering all the data. We were introduced to a surprise👻 activity that utilises all the data we had just collected.

The objective of the activity was to knock down the above cut-outs of our lecturers using the catapult, there were 4 total cut-outs. The cut-outs were placed at various distance and angles from the catapult and so we had to adjust the catapult using the data collected in order to knock the cut-outs down.

To up the stakes of this activity, our grades will actually be on the line depending on how well we did relative to other groups. This actually made it much more competitive and was extremely exciting to me. My group utilise every moment and resources to maximise the chance we can knock down the cut-outs. We discussed and tested out our catapults multiple times before we began our official attempt.

We were actually the third team to attempt this challenge as we had taken a lot of time planning beforehand. I was actually quite nervous as the two teams before us only took down 2 of the cut-outs so the challenge seemed extremely hard for me.

Fortunately, taking our time allowed us to perfect our plan and we were actually able to knock down all of the cut-outs!!

I was quite proud of actually completing the challenge as a group and I can only thank my groupmates for putting in so much effort into this practical.

Overall, this practical has been extremely fun. Although, the collection of data was quite tedious, by being able to study the data and plan out our attempt for the challenge it ended up being extremely worth it in the end.

Thank you for reading my blog till the end! Please stay tuned for my next blog entry, bye!!!

Comments

Post a Comment