Welcome back everyone! 👋 Thank you for reading my blog entry again. This blog entry will be talking about gears ⚙⚙⚙ as well as sharing my experience of the gears practical.

Gears Background Introduction

Wheels with teeth are called gears. Gears can be used to change direction of rotation, transmit force and increase speed.

In a gear train, there will be a driver and driven gear. The driver gear will often be connected to a motor shaft which allows the driver gear to turn. A driven gear has its teeth meshed with driver gear and will turn in the opposite direction of the driver gear.

In a gear train there could also be an idler gear.

Another type of special gear is a compound gear.

A compound gear has multiple gears fixed together. Its key feature is that all the gears fixed onto a compound gear will have the same speed. As such compound gear can be used to control the speed of the output of the gear train.

Compound gears can be used to form a special type of gear train, compound gear train.

KEY TERMS IN GEARS

- Gear module : refers to the size of a gear. If two gears are meshed correctly together, they will have the same gear module.

- Pitch circular diameter: refers to the diameter of the pitch circle which is an imaginary circle that passes through the middle of the teeth on a gear.

- Gear ratio: refers to the number of teeth of the driven gear against the number of teeth of the driver gear.

RELATIONSHIPS BETWEEN KEY TERMS

Gear module, pitch circular diameter and number of teeth.

Gear module = pitch circular diameter / number of teeth

Gear ratio, speed ratio and output speed.

Gear ratio have an inverse relationship with speed ratio while speed ratio have a direct relationship with output speed.

Hence, when gear ratio increases, speed ratio decreases and output speed decreases.

Gear ratio and torque.

Gear ratio = Output torque / Input torque

Hence, as gear ratio increases and the same amount of input torque, the output torque will also increase.

Gear ratio have a direct relationship with output torque.

GEARS PRACTICAL

In this practical on gears, there were two activities that were conducted.

- Assembling a hand powered fan

- Arranging gears so that gear ratio will be enough to lift a water bottle 200mm off the ground

Assembling a hand powered fan

Total gear ratio = 0.10125

Total speed ratio = 9.88

Therefore the fan will rotate around 9.8 times.

Video of assembled fan:

Improvements to hand powered fan design

One way of improving the hand powered fan is to increase the number of rotations produced with every crank of the fan.

To increase the number of rotations, the speed ratio must also increase which is done by decreasing gear ratio.

Hence, the gears in the hand powered fan needs to be rearranged in order to achieve a lower gear ratio.

Sketches for better hand powered fan:

With this design the gear ratio is much lower leading to higher speed ratio and more rotations is produced for every crank of the handle.

Thus, this design will be an improvement.

Arranging gears to lift water bottle

The first thing my team did is to theorise on what would be the best way to arrange the gears.

Our thinking was that we wanted to maximise the amount of torque while not caring about the output speed. Hence, we arranged the gears in such a way that ensures input gear is smaller than output gear.

Below is the sketch of our design:

From our design, we then calculated the gear ratio of our design to see if it meets our needs.

Shockingly we actually reached a total gear ratio of 26.67!! 🎉🎉Which is way higher than what we expected. 🤯

As a result, our design was actually really good for accomplishing the activity ahead and ended ensuring a smooth way towards the goal.

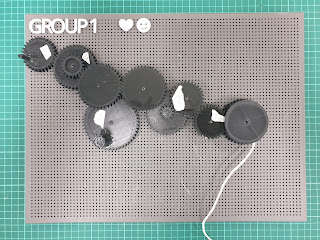

After deciding that our design was good, we then arranged the actual gears together, here is a photo of our final design:

We then calculated the theoretical amount of rotations it will take to pull the bottle up 200mm.

Finally, we operated the gears and here is the video:

It was a success!! 👏👏 The high gear ratio actually made it extremely easy to crank the handle and required minimum efforts. With this I have completed the gears practical!

LEARNING REFLECTIONS

Before this practical, I already know that gears are all around us and that it is frequently use in anything mechanical that moves such as in bicycles and elevators. However, my knowledge on how it works is limited. The most I knew was how the gears would move when interacting with each other by simple logic.

As such going into the practical I would have absolutely no idea what to do. Luckily, my lecturers provided 4 videos which was really informative while being under an hour in total. It taught me about gear ratio, torque and idler gears which were all important knowledge for the upcoming practical. As a result, going into the practical I actually had plenty of confidence in accomplishing the activities.

My team also helped me a lot whenever I struggled 😅, especially during the part of assembling the hand powered fan as I am not good with small parts. So I am grateful for them as well .

I am extremely proud of our group for being able to assemble such a high gear ratio of 26.7 which was much greater than the second highest in class of 5. As a result, we did not meet with any struggle during the cranking of the handle.

Overall, I am satisfied with my team's performance in the practical and had lots of fun applying what I have learnt about the gears in the practical 👍. I especially liked the strategic nature of planning how to arrange the gears which allowed me to utilise my knowledge on gear ratio and gear trains to accomplish a high gear ratio.

This practical will also be really helpful in my upcoming project as I am considering on using gears to create a door handle sterilizer! There is still much that I can learn about gears such as maintenance and using lubricants which I will eventually learn about as I continue my journey!

Thank you for following me through this blog entry! Please look forward to my next blog in about two weeks! Bye! 👋👋

Comments

Post a Comment